Introduction

Our team was entrusted with the task of creating a robust and efficient frame design for a Quarry Crusher Shed, a critical component within the mining and aggregate industry.

This structure plays a pivotal role in housing heavy machinery, ensuring their safety, and maintaining continuous production.

Challenges

1. Heavy Equipment Loads

The frame needed to be engineered to support the substantial weight and dynamic loads generated by large crushers and conveyors, demanding a high level of precision in design.

2. Harsh Environmental Conditions

The shed would be subjected to severe weather conditions, including extreme rain, wind, and temperature fluctuations, necessitating materials and designs capable of withstanding these environmental challenges.

3. Space Optimization

The design had to maximize the available space while accommodating various machinery configurations within the shed.

4. Safety Compliance

Adherence to industry-specific safety and code regulations was paramount to ensure the well- being of personnel and equipment.

Solutions

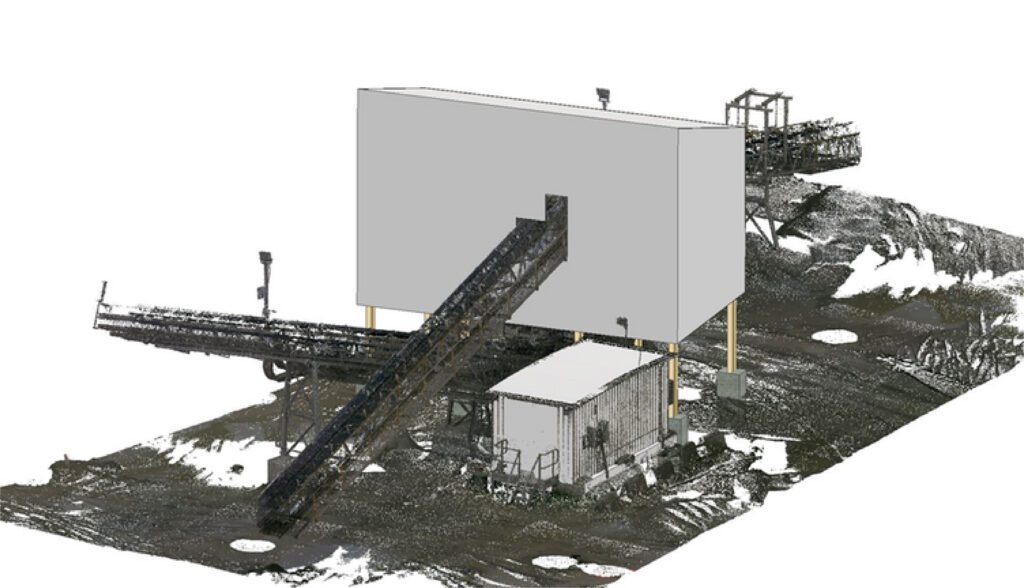

1. Advanced 3D Analysis

Our team leveraged state-of-the-art structural analysis and design software to conduct a detailed three-dimensional structural analysis. This enabled us to precisely calculate load-bearing requirements, assess potential weaknesses, and optimize the design for safety and performance.

2. Material Selection

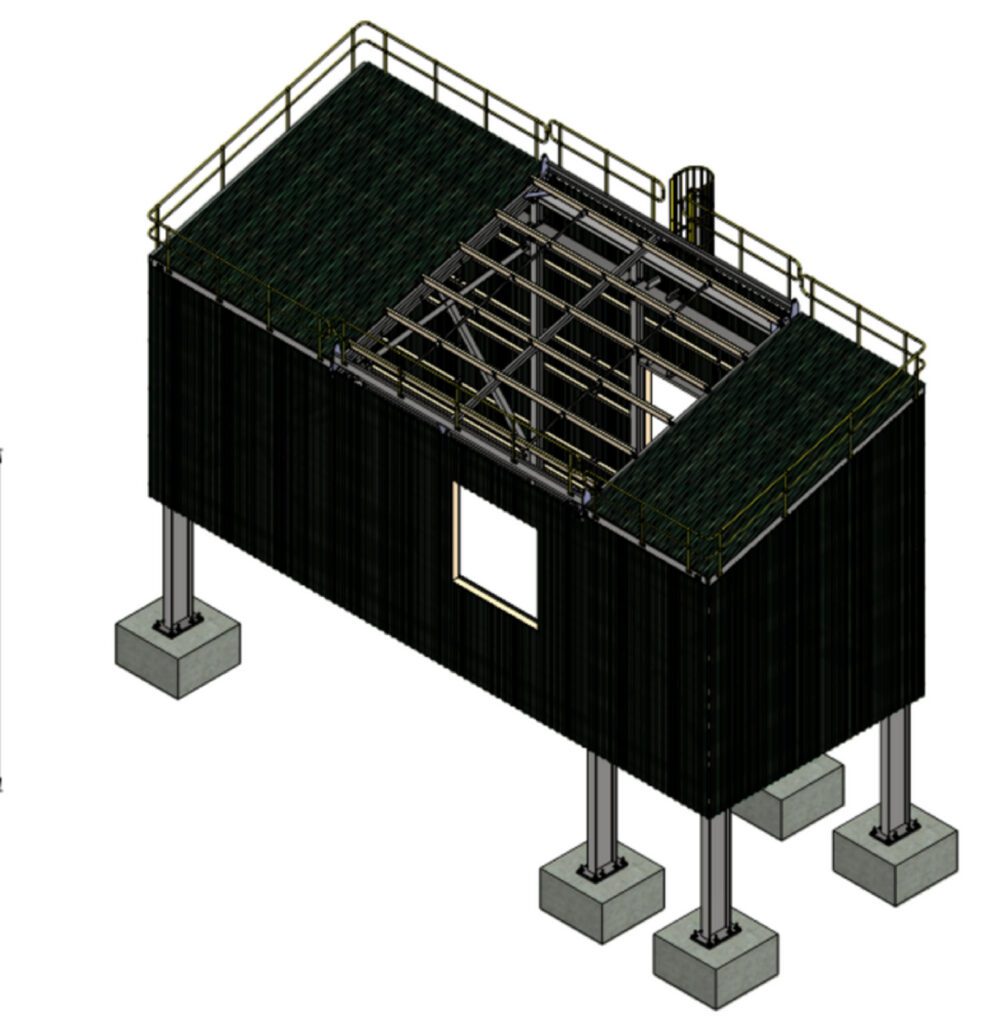

Informed by the results of our 3D analysis, we chose materials recognized for their durability, corrosion resistance, and high load-bearing capacity. High-strength steel was our material of choice to ensure the longevity and safety of the frame.

3. Customized Design

Using software programs, we developed a tailored design that maximized the use of available space, efficiently accommodating the machinery while maintaining safety standards.

4. Environmental Resilience

We implemented protective coatings and designed efficient drainage systems within the frame structure to protect against harsh weather conditions and prevent water accumulation.

5. Safety Features

To enhance safety, our design incorporated anti-vibration solutions, non-slip flooring, and clear safety signage, aligning with strict mining industry regulations.

Our innovative structural design for the Quarry Crusher Shed frame, supported by advanced 3D analysis through software programs, successfully addressed the unique challenges of the mining industry. It provided exceptional support for heavy machinery loads and demonstrated resilience in the face of harsh environmental conditions.

Space optimization within the structure, despite its considerable dimensions, enhanced machinery placement and operation, contributing to increased productivity and ensuring the highest safety standards. The software program analysis was instrumental in achieving precision and confidence in our design.

The client commended our design for its reliability and compliance with industry regulations. This project serves as a testament to the power of cutting-edge technology in structural engineering, emphasizing safety, efficiency, and resilience within challenging environments.

Our Clients

Our clients receive innovative and cost-effective solutions, working together from concept development, through to construction & commissioning and asset management – throughout the asset life cycle. Unlike typical consultants, we understand real project needs and push the boundaries to realise the project’s true potential.