Introduction

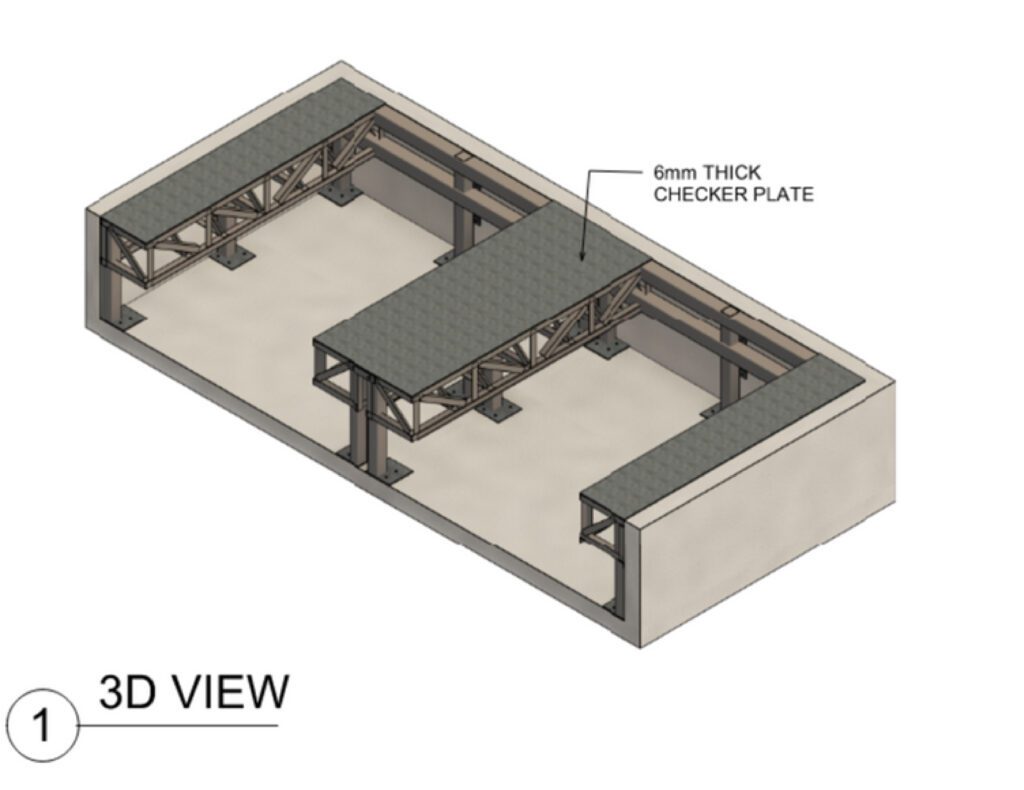

The project involved the design documentation of two dock leveller supports.

The primary objective was to ensure that the designed supports could safely accommodate a dock leveller with a 13,000 kg roll-over load and an 8,200 kg dynamic load. The support structure comprised columns, trusses, SHS beams, and a footing.

Challenges

1. Load Requirements

The most significant challenge was to design the structure to withstand the substantial roll- over and dynamic loads imposed by the dock leveler. These loads were significantly higher than typical commercial or industrial structural requirements.

2. Fixed Connections

The need for fixed connections in the support structure to resist lateral loads posed another challenge. These connections had to be designed to ensure the structure’s stability under various conditions.

3. Interfacing with Existing Dock Leveller Design

The SHS beams and framing for the dock leveller were designed by others and had to be integrated with the support structure. This required careful coordination and compatibility between the two components.

4. Adherence to Australian Standards

The project required strict adherence to various Australian Standards

Solutions

1. Load Analysis

Detailed load analysis was conducted to determine the structural requirements for the dock leveler supports. Finite element analysis was used to simulate load scenarios and ensure the structure’s stability and safety.

2. Design Verification

All structural steel members were designed in accordance with relevant Australian Standards, and the project design criteria. The calculations and structural elements were rigorously reviewed and verified to meet the required standards, ensuring that the structure could handle the specified loads.

3. Fixed Connections

Special attention was given to the design of the fixed connections. Welded connections were employed to ensure the structural integrity and resistance to lateral loads.

4. Interfacing with Dock leveller Framing

Coordination with the team responsible for the SHS beams and dock leveller framing was crucial. Detailed design meetings and reviews were conducted to ensure that the dock leveller’s framing and support structure could be seamlessly integrated.

5. Documenting Compliance

Comprehensive documentation was prepared to demonstrate compliance with Australian Standards, including detailed design calculations, drawings, and structural analysis reports. These documents served as a reference for the design and as proof of compliance.

Conclusion

In conclusion, the successful design of the dock leveller supports at 22 HAKKINEN ROAD, WINGFIELD SA 5013, demonstrated the capability of the engineering team to overcome significant challenges in structural design. Through rigorous analysis, adherence to standards, and effective collaboration with other design teams, a safe and robust support structure was developed to meet the unique demands of the project. This case study serves as an example of how complex structural engineering projects can be managed and executed effectively while ensuring safety and compliance with industry standards.

Our Clients

Our clients receive innovative and cost-effective solutions, working together from concept development, through to construction & commissioning and asset management – throughout the asset life cycle. Unlike typical consultants, we understand real project needs and push the boundaries to realise the project’s true potential.